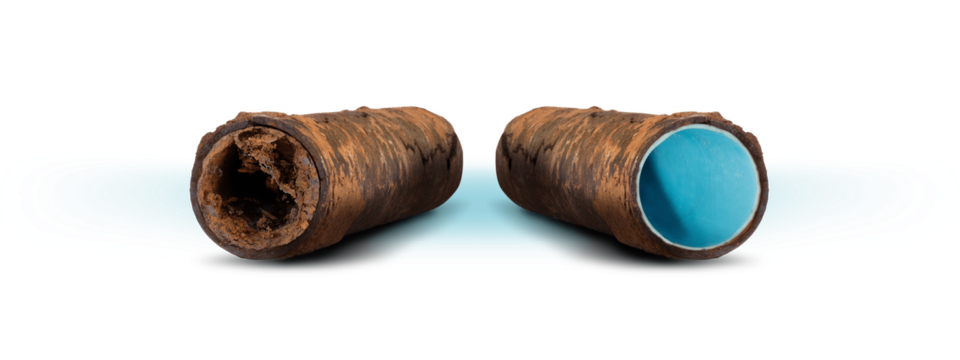

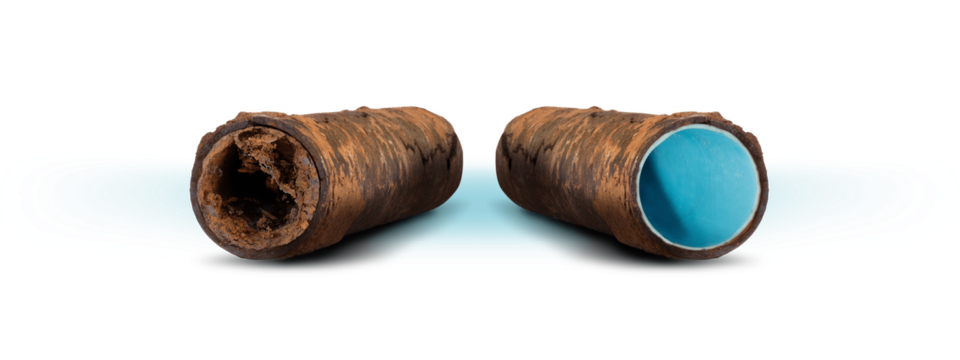

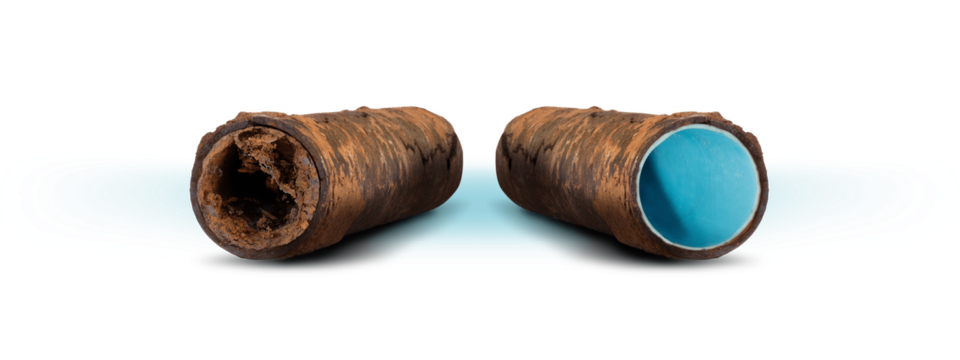

1. When considering if pipelining is worth it, it's important to note that it's not always the best solution. However, when dealing with cast iron pipes that have channel rot, pipelining proves to be the right solution around 95% of the time. There are specific situations where pipelining may not be suitable, such as when a pipe has a belly, certain types of offsets depending on the direction of the offset, or if there's a bad pitch. But for cast iron pipes affected by channel rot, pipelining effectively addresses the issue in 95-99% of cases.

2. Pipe lining generally has a life expectancy of around 50 years, which is considered the standard. However, it's important to distinguish between life expectancy, manufacturer guarantees, and warranties. Many contractors advertise a 50-year guarantee based on what manufacturers provide. Still, it's often challenging to get this guarantee honored by manufacturers of CIPP (Cured-In-Place Pipe) because the mixing and installation are done onsite.

The more crucial factor is what the installer offers regarding a warranty that covers both materials and labor. It's wise to seek the strongest possible warranty from the installer, ensuring they will cover these aspects if issues arise. Most pipe linings should last without failure when installed correctly, highlighting the importance of a solid warranty and proper installation.

Pros of Pipe Lining:

1. Less Disruption: The trenchless nature of pipe lining means less excavation, which minimizes disruption to landscapes, driveways, and structures.

2. Cost-Effective: With less labor and restoration needed, pipe lining is often more affordable than traditional pipe replacement.

3. Faster: Repairs can often be completed within a day or two, reducing downtime for homeowners and businesses.

4. Extended Lifespan: The new liner creates a durable, corrosion-resistant inner surface, often extending the life of the existing pipes by up to 50 years.

5. Versatility: It can repair various types of pipes, such as cast iron, clay, and PVC, making it suitable for many situations.

Cons of Pipe Lining:

1. Not Always Applicable: In cases where pipes have bellies, offsets, or poor pitches, or when pipes are severely collapsed, traditional replacement might be necessary.

2. Initial Cost: Although cost-effective compared to full replacement, the initial investment can still be substantial, depending on the scope of the project.

3. Warranty Challenges: Manufacturer guarantees may be hard to claim if installation issues arise because mixing and installation are done onsite.

4. Limited Diameter Changes: Pipelining reduces the inner diameter slightly, which can be a concern for pipes already at capacity.

5. Material Compatibility: Not all pipe materials are suitable for pipelining, which limits its applicability in some cases.

Pipe Lining vs. Replacement:

Pipe Lining:

Pros:

1. Less Disruption: It's a trenchless process, meaning there's minimal digging and disruption to property.

2. Faster:Repairs can often be completed in days, reducing downtime.

3. Cost-Effective: Fewer labor and restoration costs make it more economical than replacement.

4. Extended Lifespan: Lining can add decades of life to existing pipes.

5. Corrosion Resistance: The new liner is corrosion-resistant and prevents future leaks.

Cons:

1. Applicability Limitations: Not suitable for pipes with severe structural issues like bellies or collapsed sections.

2. Initial Cost: While cheaper than replacement, the upfront cost can still be significant.

3. Inner Diameter Reduction: The liner slightly reduces the pipe's inner diameter, which may affect capacity.

Pipe Replacement:

Pros:

1. Long-Term Solution: New pipes offer a clean slate and longer-term reliability, especially with modern materials.

2. Increased Capacity: Replacement allows for upgrading to larger pipes if needed.

3. Customizable: Tailored to specific needs, such as changes in pipe direction, capacity, or materials.

Cons:

1. Higher Cost: Excavation and restoration lead to higher costs than lining.

2. Significant Disruption: Digging up large areas can be disruptive to landscaping, driveways, and structures.

3. Longer Time: Full replacement can take weeks to complete due to the excavation and restoration involved.In summary, pipe lining is less disruptive and often cost-effective for mild to moderate repairs. In contrast, replacement is necessary for severely damaged or failing pipes that require a more comprehensive solution.

Pipe Lining vs. Pipe Bursting:

Pipe Lining:

Pros:

1. Minimal Excavation: The trenchless process requires little digging, reducing damage to landscapes and structures.

2. Quick Repairs: Repairs can often be completed in one or two days, limiting downtime.

3. Cost-Effective: Lower costs compared to full replacement, primarily due to less labor and restoration.

4. Extended Lifespan: Adds decades of life to existing pipes with a corrosion-resistant liner.

5. Suitable for Various Pipes: Can be used on different materials like cast iron, clay, or PVC.

Cons:

1. Limited Applicability: Not effective for pipes with significant structural issues like severe collapses or bellies.

2. Diameter Reduction: The liner reduces the inner diameter slightly, which could impact capacity.

3. Initial Cost: While cheaper than replacement, the upfront cost can still be significant.

Pipe Bursting:

Pros:

1. Increased Capacity: Allows for the installation of a larger diameter pipe than the original.

2. Complete Replacement: Replaces the entire pipe with new, durable material that addresses significant structural issues.

3. Relatively Quick: Although more invasive than lining, it is still faster than traditional excavation methods.

4. Durability: The new pipes offer high resistance to corrosion and root intrusion.

Cons:

1. Excavation Required: Requires access points to be dug for bursting and pulling equipment.

2. Potential Obstructions: Not suitable for pipes near other utility lines or those that have significant bends.

3. Higher Cost than Lining: Pipe bursting is generally more expensive than lining due to more excavation and equipment requirements.

Summary:

Pipe lining is suitable for minor to moderate repairs where minimal disruption is a priority. It extends the lifespan of pipes efficiently but is limited in applicability when structural damage is severe. Pipe bursting, on the other hand, is ideal for replacing an entire pipeline, especially when upsizing or when complete failure has occurred.